Transglutaminase Powder

Molecular Formula:C27H44O3H2O

EINECS:232-554-6

MOQ:25KG

Package:25Kg/barrel

Payment: T/T,VISA,XTransfer,Alipay

Shipping Speed: 3-5 days

Certification: ISO9001, ISO22000, Kosher, Halal, HACCP

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

What is Transglutaminase?

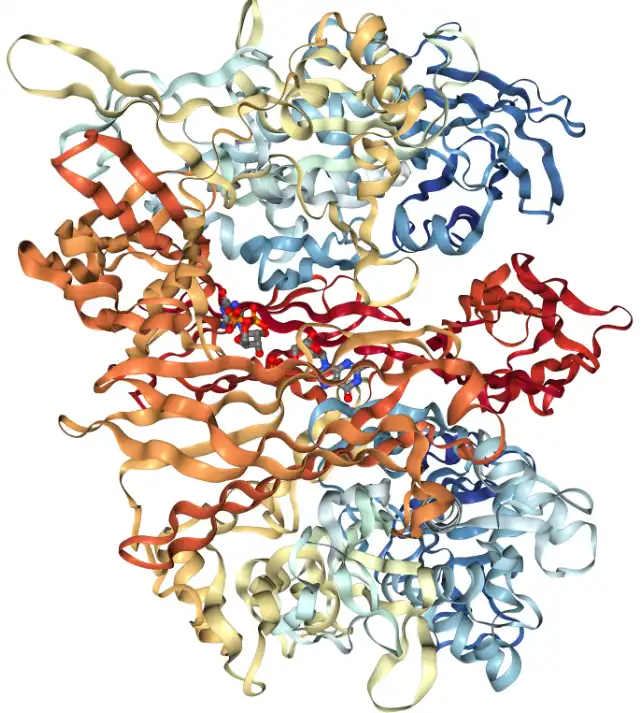

Transglutaminase Powder, referred to as TGase or TG, is an acyltransferase composed of 331 amino acids with a molecular weight of about 38,000 and a monomeric protein with an active center. This enzyme is widely present in the human body, higher animals, plants and microorganisms, and can catalyze the cross-linking reaction between glutamine residues between or within protein molecules and the amine groups of other proteins or amino acids, thereby changing the structure and function of the protein. It plays an important role in cell growth, differentiation, apoptosis and other processes, and is one of the key enzymes to maintain cell homeostasis and function. It can improve the structural and functional properties of proteins and give food proteins a unique texture and taste, so it has been widely used in food processing industries such as meat products, aquatic products, soy products, flour products, rice products and dairy products.

Product Details Table

| Product Name | Transglutaminase |

| CAS | 80146-85-6 |

| Molecular formula | C27H44O3H2O |

| EINECS | 232-554-6 |

| Solubility | H2O: soluble1.0mg/mL, clear |

| Storage Conditions | -20°C |

Features

Strong adhesion: The covalent bonds formed are difficult to break under general non-enzymatic conditions, and are often used in food processing to improve the adhesion of food components, such as for the adhesion and structural enhancement of minced meat in meat products.

Good pH stability: It has high activity in the pH range of 5.0 to 8.0, and the optimum pH is 6-7, which is suitable for application in a variety of food systems.

Strong thermal stability: The optimum temperature is around 52°C, and the activity is high in the range of 42°C to 57°C, especially in protein food systems, which can significantly improve thermal stability.

Safe use: Since TG is widely present in animal tissues, people have been eating foods containing lysine isopeptide bonds formed by TG catalysis, so foods produced with TG are safe for the human body and beneficial to human health.

Mechanism of Action

Its mechanism of action mainly depends on its catalytic activity. It can transfer glutamine residues from donor proteins to acceptor proteins to form covalently linked isopeptide bonds. The formation of this isopeptide bond enables protein molecules to connect to each other, forming a more complex network structure. In addition, transglutaminase can also catalyze cross-linking reactions within protein molecules, increasing the stability and function of proteins.

Functions of Transglutaminase Powder

Improve nutrient intake and protein utilization

It can catalyze cross-linking reactions within and between protein molecules to form a more stable protein structure. This process helps to improve the nutritional value of protein, especially in food processing, by introducing essential amino acids such as lysine, it can improve protein utilization and meet the body's nutritional needs.

Promote wound healing and tissue repair

Transglutaminase Powder plays a key role in wound healing and tissue repair. It can promote cell adhesion and migration, accelerate wound closure and tissue regeneration, and help postoperative recovery, trauma treatment, and chronic wound management.

Regulate immune response

Participate in immune regulation and help maintain the balance of the immune system by affecting the activity and function of immune cells. This is of great significance in preventing infection, reducing inflammatory responses, and regulating autoimmune diseases.

Support muscle growth and recovery

In sports nutrition, it helps to promote muscle protein synthesis and repair, reduce muscle fatigue and damage after exercise, and accelerate the recovery process. This is of great significance for athletes and fitness enthusiasts to improve sports performance and muscle growth.

Support intestinal health

Promote the integrity and function of the intestinal mucosal barrier. Transglutaminase is involved in the formation and remodeling of the extracellular matrix, which is essential for maintaining the barrier function of the intestinal mucosa. It can effectively prevent the translocation of bacteria and endotoxins and reduce the risk of intestinal inflammation and infection.

Use of Transglutaminase Powder

1. The optimum pH of TG is 6~7, so when using it, the environment in which TG is used should be kept between pH 6~7, preferably not exceeding the range of 5~8.

2. The activity of TG remains stable at 40℃, and gradually weakens after exceeding 40℃. The optimum temperature for a reaction time of 10 minutes is 50~55℃. As the reaction time increases, the optimum reaction temperature will also decrease. When the temperature is high, food, especially fish, meat, dairy products, etc., is prone to deterioration. Therefore, the determination of the reaction temperature is the most critical and difficult factor to determine among all factors. Under the premise of ensuring product quality, it directly affects the amount of TG added and the length of time required for the catalytic reaction. Generally, for low-oil and easily deteriorating products such as fish, the selected reaction temperature is relatively low (1~10℃), and the corresponding reaction time is relatively long (2~12 hours or more). Generally speaking, the reaction temperature is not higher than 40℃.

3. Object of action. First of all, TG acts on proteins, and catalyzes the reaction of "reactive" glutamine residues, so the content of protein and the content of "reactive" glutamine residues have a great influence on the effect of TG, that is, not all proteins or foods containing protein are good substrates for TG.

Secondly, the presence of lysine residues is required for the reaction to occur (otherwise, the effect of TG can only be to change the solubility of proteins and related properties), that is, the content of "reactive" lysine residues also has a great influence on the cross-linking reaction of TG.

4. Common good substrates for TG include casein and its sodium salt in milk, gelatin and myosin in meat, and 11s globulin and 7s globulin in soy protein. Therefore, in order to achieve a good cross-linking effect, a good substrate for TG can be appropriately added to the target. The most commonly used ones are sodium caseinate and gelatin, as well as cheap soy protein. Here, it is particularly important to point out that:

(1) Some proteins can be hydrolyzed and heated by appropriate methods to deform the protein, but they contain more glutamyl residues and/or lysine residues. However, due to the spatial structure and other relationships, they cannot be catalyzed by TG. After enzymatic hydrolysis or heating denaturation, these residues will be exposed and become "reactive" residues, such as wheat flour protein and whey protein.

(2) Protein residues rich in reactive glutamyl residues or lysyl residues, such as glutamyl or lysine peptides, can be selectively added to supplement the deficiency of relevant amino acid residues in the target.

Application Areas

Food

Meat Processing: Improve the texture, taste and appearance of meat products, improve the water retention and elasticity of meat products, and reduce water loss during processing.

Dairy Processing: Improve the yield and quality of cheese, and improve the consistency and taste of yogurt.

Noodle Processing: Enhance the gluten strength and extensibility of dough, and improve the taste and shelf life of noodles.

Cosmetics

Improve the stability of protein in cosmetics, improve its moisture retention and film-forming properties, and enhance skin care effects.

Medicine

Drug R&D: As a target for drug development, it is used to develop drugs for the treatment of inflammatory diseases.

Tissue Engineering: Used to prepare biomaterials, such as tissue engineering scaffolds, to promote tissue repair and regeneration.

Certificates

YTBIO is developing in an all-round way. We have our own factory, quality inspection and R&D team. We are committed to providing customers with the best quality Transglutaminase Powder and services. It is our original intention to let every consumer enjoy high-quality and healthy products. If you have any needs or questions about our products, please feel free to contact us and we will reply you as soon as possible.

Packaging and Shipping

Our Factory

_1737093401309.png)