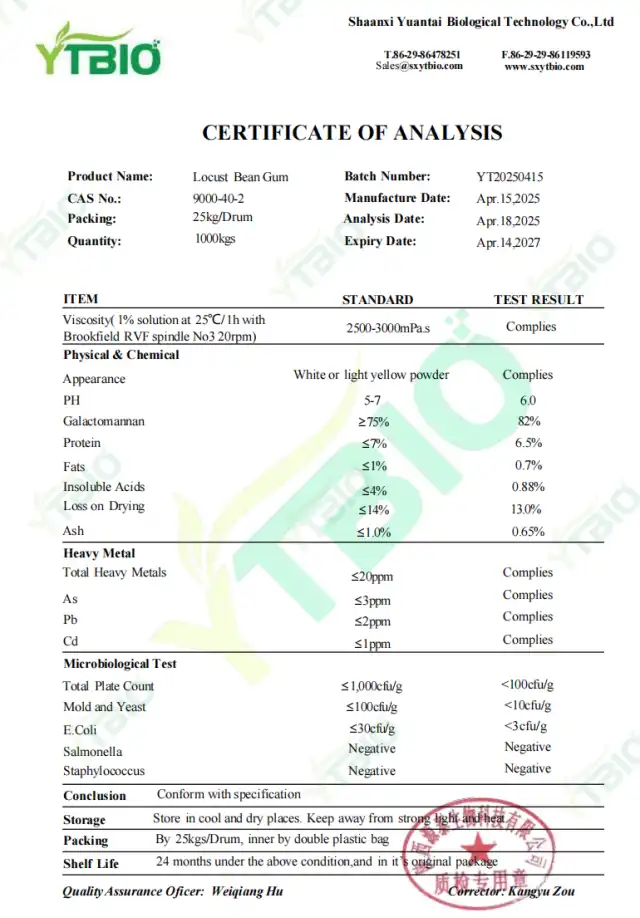

Pure Locust Bean Gum

Specifications: 800 viscosity, 3000 viscosity, 6000 viscosity, exquisite locust bean gum

Shipping speed:1-3 days

Inventory:In stock

Certificates:HACCP, HALAL, KOSHER, ISO9001, ISO22000, FDA

MOQ:25KG

Package:25Kg/barrel

Sales group:not for individual customers

- Fast Delievery

- Quality Assurance

- 24/7 Customer Service

Product Introduction

What is locust bean gum?

Pure Locust Bean Gum Powder is a plant gum processed from the seeds of the locust tree produced in the Mediterranean area. It is a white or slightly yellow powder, odorless or slightly smelly. It is mainly used as thickener, emulsifier and stabilizer in the food industry. Locust bean gum, also known as locust bean gum, locust bean gum, carob bean gum, locust bean gum, red locust bean gum, locust seed endosperm extract, is a large gum composed of galactose and mannose units combined by glycoside bonds. Molecular polysaccharide polymer, the molar ratio of the two is 1:3.324, and the relative molecular mass: 310000~2000000.

In the food industry, locust bean gum is often used as a thickener, water-holding agent, adhesive and gelling agent in combination with other edible gums. Combining it with carrageenan can form elastic jelly, while using carrageenan alone can only obtain brittle jelly.

Compounding it with agar can significantly improve the bursting strength of the gel. It is widely used as a composite gelling agent for canned foods when combined with seaweed gel and potassium chloride.

It is a good ice cream stabilizer when combined with carrageenan and CMC. It can also be used as a water-holding agent in dairy products and frozen dairy desserts to enhance the taste and prevent the formation of ice crystals.

What are the benefits and applications of locust bean gum?

Locust bean gum can be regarded as a dietary fiber and can be used as a dietary supplement in weight control and treatment of diabetes and hyperlipidemia. The generally observed physiological effect of dietary fiber is that high-viscosity fiber can serve as an adsorption and binding carrier for nutrients, which alleviates the digestive destruction and peristalsis of nutrients in the intestine, ultimately leading to a lower degree of absorption of nutrients. Low. Locust bean gum has the effect of lowering postprandial blood sugar and insulin levels in diabetics. In addition, locust bean gum also has a certain impact on the secretion of gastrointestinal hormones.

In the food industry, locust bean gum is often used as a thickener, water-holding agent, adhesive and gelling agent in combination with other edible gums.

●The viscosity is obtained after heating.

●Can produce good texture and fragrance release.

●LBG aqueous solution has high viscosity at low concentration, and the colloid can effectively hydrate and prevent dehydration.

●Normally, locust bean gum alone cannot produce gel, but when combined with kappa carrageenan/agar, it can form a very elastic gel. When kappa carrageenan or agar is used alone, it can only form a brittle gel. of gel.

●When compounded with xanthan gum, it can form a gel. When used alone, these two products can only thicken but cannot form a gel. This synergistic property is widely used in ready-to-eat (RTC) product dessert jelly to Improve product shelf life.

Application of locust bean gum in food field

1. The combination of locust bean gum and carrageenan can form elastic jelly, while using carrageenan alone can only produce brittle jelly.

2. Locust bean gum, seaweed gum and potassium chloride are widely used as compound gelling agents in pet cans.

3. The combination of locust bean gum/carrageenan/CMC is a good ice cream stabilizer, with a dosage of 0.1-0.2%.

4. Locust bean gum is also used as a water-holding agent in dairy products and frozen dairy desserts to enhance the taste and prevent the formation of ice crystals;

5. Used in puffed food to provide lubrication during extrusion processing, and can increase output and extend shelf time;

6. Used in flour products to control the water absorption effect of dough, improve dough characteristics and quality, and extend aging time.

The viscosity of locust bean gum increases with the increase of concentration, and it is a non-Newtonian fluid, and its viscosity decreases with the increase of shear speed; the viscosity of locust bean gum can be increased when heated below 80℃, and the viscosity of locust bean gum is increased at 60℃ The optimal heating temperature of locust bean gum; freezing has no effect on the viscosity of locust bean gum solution, while refrigeration can reduce the viscosity of locust bean gum. And locust bean gum is relatively stable in acidic solutions and alkaline solutions.

Properties of locust bean gum

1. Colorless, odorless plant endosperm refined polysaccharide, mainly containing mannose and galactose, is an extremely good thickening stabilizer.

2. The viscosity of locust bean gum increases with the increase of concentration. When the concentration is 2%, the viscosity is 46.4MPa.s.

3. Locust bean gum is a non-Newtonian fluid, and its viscosity decreases with the increase of shear speed.

4. Heating below 80℃ can increase the viscosity of locust bean gum, and 60℃ is a good heating temperature for locust bean gum.

5. Freezing has no effect on the viscosity of locust bean gum solution, but refrigeration can reduce the viscosity of locust bean gum.

6. pH has little effect on the viscosity of locust bean gum solution, that is, locust bean gum is relatively stable in acidic solutions and alkaline solutions.

7. Interact with agar, carrageenan, xanthan gum, etc. to form complexes in the solution to enhance the gel effect.

Features

(1) locust bean gum powder is water-soluble, but insoluble in organic solvents such as ethanol. Refined grade locust bean gum has good transparency. Ordinary locust bean gum is only partially dissolved in cold water and needs to be heated to 85 degrees Celsius for more than 10 minutes to fully hydrate;

(2) Pure locust bean gum becomes viscous after being dissolved, and can be used as a thickener, emulsifier, stabilizer, etc. in food, petroleum, textile and other fields;

(3) Locust bean gum is a non-Newtonian fluid, and its viscosity is inversely proportional to shear speed and directly proportional to concentration, and the viscosity of hot-water-soluble locust bean gum is higher than that of cold-water-soluble locust bean gum; in addition, when the pH is between 3- At 11 o'clock, the viscosity of the locust bean gum solution was almost unchanged;

(4) Pure locust bean gum itself has no gel properties, but it has excellent gel synergy with other hydrophilic colloids. Through different ratios with other natural gums, the viscosity, gelling ability, elasticity and brittleness of the product can be improved. For example, elastic jelly can be made by compounding it with carrageenan.

The general process flow of extracting locust bean gum is: locust bean pods → sun drying → coarse crushing → sieving → solvent treatment → washing → drying → crushing, sieving, peeling → fine crushing → sieving → commercial locust bean gum. The key to processing locust bean gum is to reduce impurities and avoid changing the chemical structure and colloidal properties as much as possible during the extraction process.

Characteristic

Refined locust bean gum solution has good transparency and can be dispersed in hot or cold water to form a sol, while ordinary locust bean gum is only partially dissolved in water and needs to be heated to 85°C to completely dissolve, and reaches its maximum viscosity after cooling. Insoluble in organic solvents such as alcohol and grease.

Changes in pH have little effect on the properties of the gel solution within the range of 3 to 11. The viscosity of locust bean gum itself has nothing to do with its synergistic ability. The pH of 1% ordinary locust bean gum solution is between 5.4 and 6.5, and the viscosity is between 1.5 and 4.0 Pa·s. The viscosity is lower than that of guar gum, depending on the grade of locust bean gum.

Locust bean gum solution has pseudoplastic fluid properties and has a diluting effect. In addition, the plastic deformation value of the locust bean gum solution is zero, so as long as the slightest edge cutting force is applied, the solution starts to flow. The apparent viscosity of locust bean gum decreases rapidly with the increase of shear speed, and then stabilizes and approaches the lowest limit value. This value depends on the concentration of the solution. At any given shear speed, the apparent viscosity of the locust bean gum solution was not affected by the time of the test and previous shear tests. As long as the applied shear speed does not cause the cleavage of the molecular structure, whether the final shear speed is from high to low or from low to high will not affect the results of the test.

Locust bean gum itself does not form a gel. Because there are relatively more unsubstituted mannose groups in the galactomannan structure of locust bean gum, the interaction with other gums such as xanthan gum is more obvious than with guar gum. Locust bean gum forms a complex with these polymers in solution to form or enhance the gel effect. Locust bean gum has a synergistic effect with natural food gums such as guar gum, agar and kappa carrageenan, which can greatly increase its viscosity, gelling ability and strength. According to different proportions, jelly of various elastic and brittle specifications can be made.

Locust Bean Gum Supplier

Yuantai Organic Bio is committed to providing customers with the highest-quality Pure Locust Bean Gum powder and services so that every consumer can enjoy natural, healthy, and high-quality food. If you have any inquiries or needs about our products, please feel free to contact us, and we will reply to you as soon as possible.

Hot tags:Locust Bean Gum,Suppliers, Manufacturers, Factory, Buy, price, for sale, producer, free sample, OEM, ODM, private label, white label.

_1737093401309.png)